direct drive motor coupling

An electric motor is an electrical machine that converts electrical energy into mechanical energyMost electric motors operate through the interaction between the motors magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motors shaft. In a magnetic drive pump the wet end and motor are two separate parts connected by a motor bracket.

A motor with a 115 service factor can be expected to safely handle infrequent loads to 15 past its rated horsepower.

. A belt drive system isnt as common as a chain drive system though in terms of popularity it stands at a distant second position. This setup comprises of a driving pulley towards the gearbox output shaft and a driven pulley at the wheel the two pulleys are connected by a belt which has teeth or grooves on the inner side matching the. Most commonly specified coupling type - cost effective.

Calculate the value for load torque load inertia speed etc. The Bi-Polar electric locomotives built by General Electric for the Milwaukee Road had direct drive motors. The rotating shaft of the motor was also the axle for the wheels.

The three electric motors constitute the most powerful electrical motor set-up in production car history replacing the gears of a normal transmission. M Direct Coupling FA F-3 Tec hnical Reference Standard AC Motors Speed Control Systems Stepping Motors Gearheads Motion Cooling F ans Motor and F an. A Direct Drive Linear DDL motor is basically a rotary motor that is laid out flat and directly coupled to the driven load eliminating the need for balllead screws rack and pinions beltspulleys and gearboxes.

Damages in the drivetrain can only be avoided by an overload protection at the propeller shaft. Even when mounting a full-sized stepper motor and the stock Creality components the MDD v13 weighs only 459g thats just 30g over a similarly equipped Hemera for reference. Fits 1340 1440 1535 1541 1641 1782 1860.

The challenge is the design of an overload protection which can limit the torque reliable and is small enough for an installation in the available space in the thruster housing 14. Sure Motion JawSpider Clamp-Style Drive Couplings. The motor side coupling can reduce overloads at the motor.

In the case of French TGV power cars a motor mounted to the power cars frame drives each axle. There is one YASA motor for each rear wheel providing electric direct drive and one on the crankshaft that provides torque-fill electrical generation and starter motor functionality. At the motor drive shaft of the mechanism.

Direct Drive Linear Motors. Planetary gearboxes worm reducers in-line helical gear speed reducers parallel shaft helical gear reducers helical bevel reducers helical worm gear reducers agricultural gearboxes tractor gearboxes auto gearboxes pto drive shafts special reducer related gear. A 10 hp motor could run at 115hp.

Hzpt group co ltd. A downside is a hot motor with a shorter expected life. New Hydro Gear transmission assembly wheel motor final drive PN 618-3218B USE 918-3218B.

A tripod drive allows a small amount of flexibility in the drive train. Drive coupling With O-ring groove PN 748-3030 748-3030A. In direct drive the impeller of the pump is attached to the shaft of the motor and this design depends on the Mechanical shaft seal.

Because the MDD is completely modular it enables some of the lightest direct drive combinations in the world with some combinations weighing less than 330g. For example a motor with a 10 service factor cannot be expected to handle more than its nameplate hp on a continuous basis. An electric generator is mechanically identical to an electric motor but operates.

Magnetic Coupled refers to the coupling between the wet end of the pump and the motor. Aluminum hubs available with different bore diameters in same coupling. Polyurethane center spiders available in different durometers for different degrees of shock and vibration reduction.

Direct replacement for original ISO mounts. Refer to page 3 for calculating the speed load torque and load inertia for various. Is specialist in making all kinds of mechanical transmission and hydraulic transmission like.

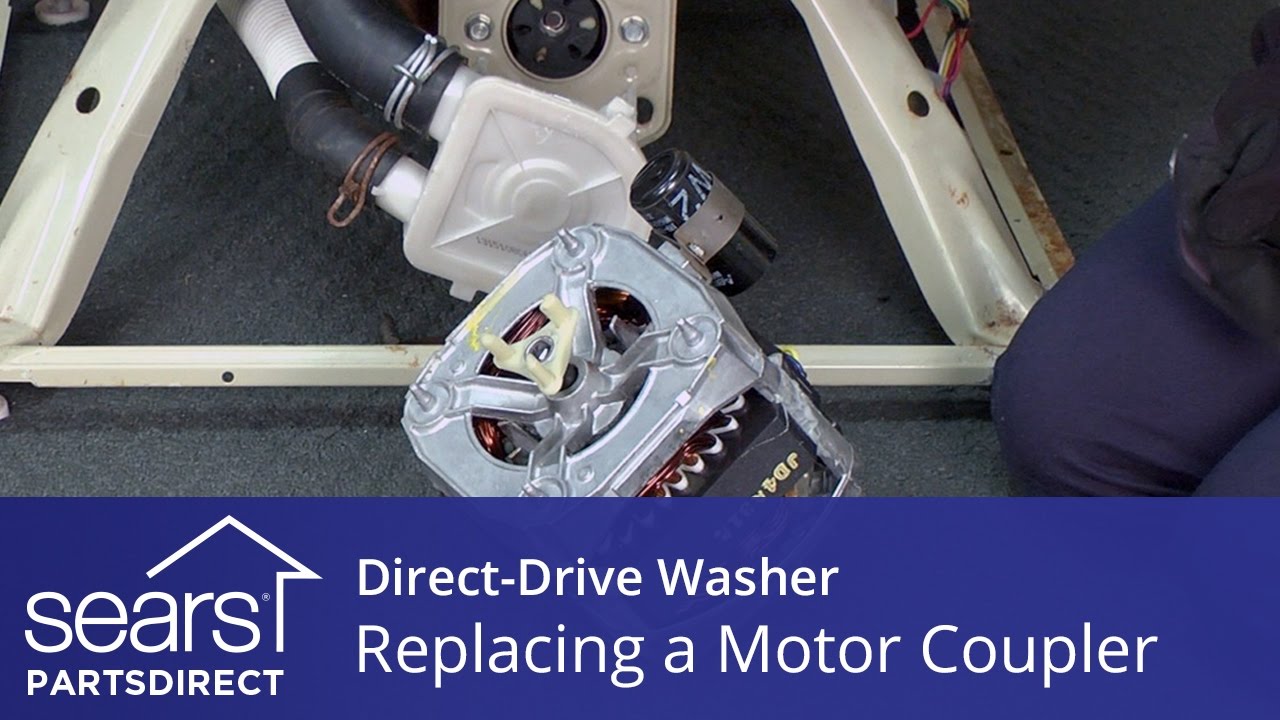

Whirlpool Washer Repair How To Replace The Direct Drive Motor Coupling Youtube Washer Repair Whirlpool Washer Repair

Shop For Kenmore Automatic Washer Repair Parts For Model 11024924202 At Sears Partsdirect Find Parts Ma Washer Repair Washing Machine Repair Whirlpool Washer

Washer Motor Coupling Diy Repair Tutorial For Kenmore Top Loading Washers When Drum No Longer Spins Bonus Luigi S Washer Repair Whirlpool Washer Diy Repair

Motor Coupling 285753a Fast Shipping Washing Machine Motor Appliance Repair Kenmore Washing Machine

How To Replace A Direct Drive Washer Motor Coupler Kenmore Whirlpool A Kenmore Washer Kenmore Washer

Motor Coupling 285753a Order Now For Same Day Shipping 365 Day Return Policy Repairclinic Com Washing Machine Repair Appliance Repair Washer Repair

Kenmore Whirlpool Washer Not Spinning Agitator Stop Turning Replace Motor Coupler Clutch Pump Yo Whirlpool Washer Kenmore Washer Washing Machine Repair